Testing samples with direction dependent properties

The Anisotropic Module furnishes the unique ability to measure the different Thermal Transport Properties along and perpendicular to the main axis of uniaxial materials, often referred to as the in-plane and through-plane directions, respectively. The Anisotropic Module is now also updated to test the Thermal Transport Properties of biaxial materials, in which the Thermal Conductivity, Thermal Diffusivity, and Thermal Effusivity are 3D tensors.

Being able to test the 2D or 3D anisotropic behavior of Thermal Transport Properties is crucial for many applications. In any context where heating or cooling is involved, for example in batteries, electronics and building materials, being able to ascertain this property is vital. Other hot topics where measurements of the anisotropic Thermal Transport Properties are of particular interest include 3D-printing, carbon fibers and graphite laminates used in e.g. robotics, automotive and aerospace industries. This type of measurement is made possible with Hot Disk® instruments with the add-on Anisotropic Module, and by using the Specific Heat Capacity of the sample in question as input data. Specific Heat Capacity, if not found tabulated in scientific papers etc., or known from previous testing of similar materials, can readily and accurately be tested via the dedicated Hot Disk® instrument add-on measurement module – Specific Heat Capacity Module.

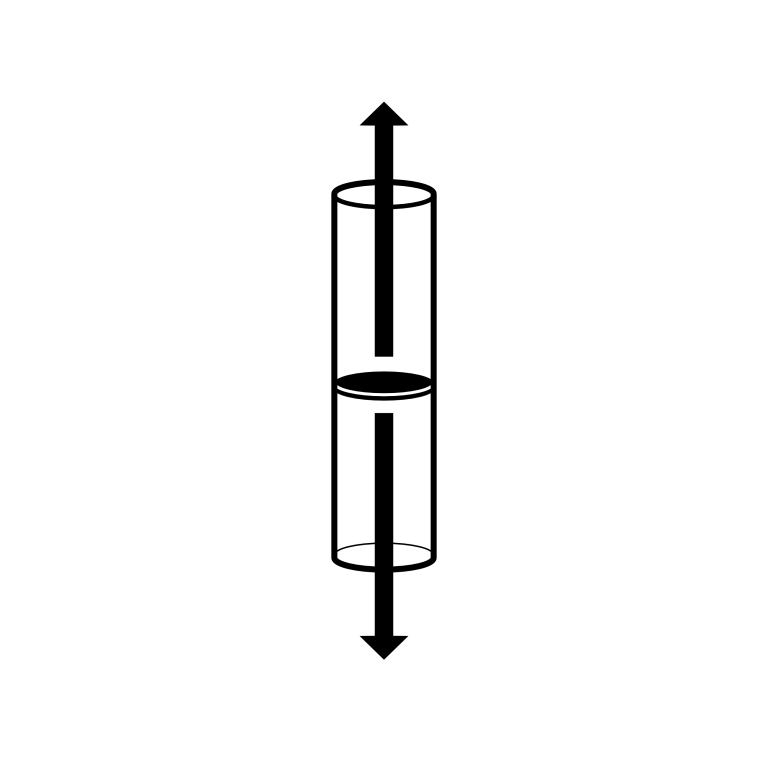

Applying the Anisotropic Module, the Hot Disk® sensor is typically used to determine the 2D anisotropic, i.e. in-plane and through-plane, Thermal Transport Properties of uniaxial materials. This while the Hot Strip sensor is used to deduce the 3D anisotropic, i.e. 3D tensor, Thermal Conductivity, Thermal Diffusivity, and Thermal Effusivity of biaxial materials. The latter capability is exclusive to our premium TPS 3500 instrument. The Anisotropic Module features both single- and double-sided sample testing, but double-sided testing is recommended for maximum precision.

Thermal Conductivity Range:

| Instruments | Range |

|---|---|

| TPS 3500, TPS 2500 S | 0.005 to 1500 W/m/K |

| TPS 2200, TPS 1000 | 0.01 to 500 W/m/K |

| TPS 1500 | 0.01 to 50 W/m/K |