Linking Science to Novel Production

Our Hot Disk® TPS 2500 instrument redefined the market in 2006, soon becoming the leading thermal conductivity meter across the globe. By 2008, our Hot Disk TPS method became the international standard for thermal property analysis. Today we have sold more than 2000 TPS systems sold worldwide. Our network extends to distributors in over twenty countries. Yet for us, success is not measured in the number of systems sold. We instead gauge success by our satisfied customers, by the scientific advancements they empower, and the accuracy and durability of our instruments.

Over 6000 published papers authored by research groups from around the world stand testament to our global impact. Our TPS method simply remains the best and most reliable way of testing thermal transport properties. It stands out in battery development, automotive analysis, aerospace research, and more – wherever rigorous and precise testing is called for.

The Hot Disk® TPS 3500 instrument is today our state-of-the-art instrument, offering unparalleled accuracy in detecting subtle material changes for cutting-edge research. The TPS 3500 also provides unique testing capabilities for diverse industries, from aerospace to textiles. With its uncompromising design and stellar performance, linking science to novel production, the TPS 3500 is a true bridge to the future. With state-of-the-art accessories and dedicated sensors, it makes a bold and confident statement in your lab. The TPS 3500 naturally meets ISO 22007-2 and also ASTM E3088-25, and is CE-marked.

Welcome to the world of Hot Disk, and its World-Leading Thermal Conductivity Meters!

World-Leading Battery Testers

Today, considerable sums are invested in rechargeable (Li-ion) battery research around the globe. Researchers and developers are seeking to reduce battery costs, sizes, weight ratios, and rates of power degradation. A significant driving force is the current and widespread electrification of vehicles, which at length will work to reduce carbon footprints in the transportation sector. Thermal runaway is a major battery damage and safety concern in this greater context, making thermal management a critical part in battery cell and battery pack development. Garnering knowledge of the thermal properties of battery materials and cells is essential for battery designers.

Thermal Conductivity, Thermal Diffusivity and Specific Heat Capacity of battery materials, cells, and packs are currently being tested with Hot Disk® instruments by hundreds of battery research laboratories world-wide – join our community!

Learn more from these publications >

Battery materials prove highly anisotropic due to their layered structures. It is not unusual that the Thermal Conductivity is 200 times higher in the in-plane compared to the through-plane direction of the layers. Our Hot Disk® sensors uniquely test the anisotropic Thermal Conductivity and Thermal Diffusivity of layered battery composites with high accuracy and precision – within seconds!

Learn more from this Application Note >

Battery cells come in various types and sizes, displaying different heat generation and dissipation properties. An essential parameter for battery pack thermal modelling is the Specific Heat Capacity of the relevant battery cell. With our Hot Cell® sensors, the Specific Heat Capacity of a battery cell of any type – button, cylindrical, pouch, or prismatic, as well as any size up to 40 cm in length – can be determined – precisely and with ease!

Learn more from this Application Note >

Global Benchmark Thermal Conductivity Meters

Hot Disk provides world-leading instruments – based on our TPS technique, invented and developed in-house – for quickly and reliably testing Thermal Conductivity, Thermal Diffusivity, Thermal Effusivity and Specific Heat Capacity of any material type. The range covers isotropic and anisotropic bulks, composites, fiber materials, laminates, stacks, sheets, foils, textiles, films, coatings, pellets, grains, granules, powders, pastes, creams, gels, liquids, insulators, and many more.

Check out our history and scientific papers >

The simplicity and flexibility of testing with the unmatched Thermal Conductivity range and precision of our Hot Disk instruments – achieved via their state-of-the-art, micro-Kelvin temperature sensitivity – has been widely acknowledged by the scientific community. As providers to researchers and industries since nearly three decades back, we have to date installed more than 2000 Hot Disk® instruments world-wide, while our customers have published over 6000 journal papers presenting their measurement data from our sterling equipment.

Check out our publications database >

From the immediate international appreciation and impact of our instruments, we were urged to file for an international standard for our TPS technique. The relevant standard was approved in 2008 – the ISO 22007-2. Ever since, Hot Disk® instruments have been deigned the global benchmark thermal conductivity meters – safeguard your materials testing by joining our Hot Disk user community!

Learn more about our ISO standard >

The state-of-the-art Hot Disk® TPS 3500 instrument

Easy, Fast & Non-Destructive Testing

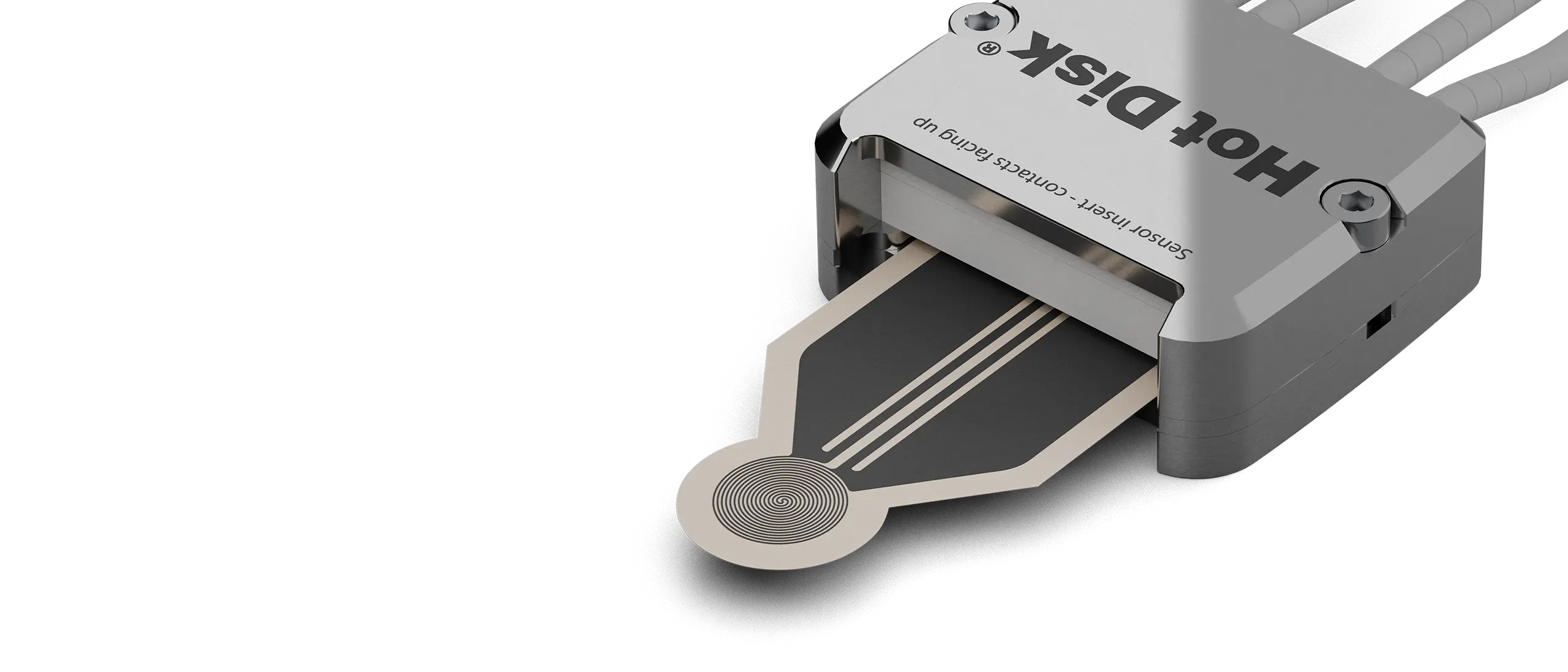

Our thermal conductivity meters are based on the Hot Disk® Transient Plane Source (TPS) technique, invented by our co-founder Dr. Silas Gustafsson in 1989. The TPS technique utilises a thin metal foil sensor that has a double-spiral formed over a disk area. The metal foil is laminated with thin electrically insulating layers.

The ensuing testing then follows by simply placing our patented Hot Disk® sensor on the surface of a sample, or by sandwiching the sensor between two sample pieces. The former enables simple testing for QC scenarios, while the latter provides the highest accuracy for R&D contexts. There is no need for fixed geometries, contact agents or surface modifications – simply test your samples as they are!

During a measurement, the chosen Hot Disk® sensor functions both as heater and thermometer. From a single heat pulse issued, the recorded temperature rise of the sensor allows one to extract both the Thermal Conductivity and Thermal Diffusivity of the sample. From these two properties, the Thermal Effusivity and Specific Heat Capacity can in turn be computed. Simply put, all four properties are obtained by a single quick measurement – within seconds!

Check out our history and scientific papers >

The Hot Disk® instrument range is remarkable, tackling samples of:

- Thicknesses spanning several centimeters down to below 10 micrometers;

- Thermal Conductivities ranging from below 0.005 W/mK to beyond 1800 W/mK; and

- Ambient temperatures spanning less than 20 Kelvin to beyond 1000°C.

Learn more about the capabilities of our famed instruments >

Industry Standard Polymer Testers

Hot Disk® instruments are today the industry standard for testing Thermal Conductivity, Thermal Diffusivity and Specific Heat Capacity of polymers, c.f. our international standard for plastics – ISO 22007-2.

Learn more about our ISO standard >

Thermoplastics are an important component of everyday life, for example in sports equipment, toys, food storage containers, cleaning products, medical items, automotive parts, and electrical insulations. They are made of polymer compounds plus additives, and their thermal, electrical and mechanical properties can be tailored via particle fillers (ceramic, metal, graphite etc.) and fiber reinforcements (glass, carbon, aramid, basalt etc.).

Carbon fiber reinforced polymers (CFRPs) and thermoplastics with carbon or metal fillers are hot R&D topics today. The overall aim is to maximize the plastic composites’ mechanical strength and thermal management, which is critical for high-tech applications within innovation-driven automotive, aerospace and electronics industries.

Carbon fiber reinforced polymers are anisotropic materials. They display significantly different Thermal Conductivity in and through the plane of the fiber alignment, typically some 50 times higher in the in-plane direction. This inhomogeneity can readily be tested with high accuracy by Hot Disk® instruments – with our anisotropy analysis!

Learn more from these publications >

Thermoplastics added with carbon/graphite flakes or metal powders can substantially increase the Thermal Conductivity of composites, indeed by up to several hundred percent. The delicate super-linear dependence on Thermal Conductivity with volumetric filler content is easily detected by our Hot Disk® Thermal Conductivity Meters – due to their state-of-the-art precision!

Learn more from these publications > and from this Application Note >

What is Your R&D Topic?

Today, our customers successfully tackle applications involving lithium batteries, graphene-based nanocomposites (GNCs), thermal interface materials (TIMs), fibre-reinforced polymers (FRPs), smart textiles, nanofluids, aerogels, 3D-printed materials, thermoelectrics, phase-change materials, metals, ceramics, building materials, gastronomic and alimentary products, as well as geological samples.

This signal feat is made possible with Hot Disk® instruments and sensors, coupled as these are to a market-leading range of specific, tailored measurement modules. All integrate the absolute Transient Plane Source or TPS method, invented and developed in-house, so ensuring our clients the most accurate and reliable results one may obtain today.

Please consult our comprehensive and continually updated publications database for independent verification of our vast and reliable applicability. Here you can search among thousands of journal papers where Hot Disk® instruments are employed and create value. When you choose to invest in our hardware, you ensure having the most flexible and reliable Thermal Conductivity meter available at your side, tackling all kinds of sample types – coatings, films, sheets, slabs, stacks, laminates, composites, rods, bulks, solids, crystals, minerals, semiconductors, granules, powders, pastes, gels, liquids, insulators, textiles, and more.

Check out the hot topics in our publications database > and our range of Application Notes >

Testing Anisotropy and Structural Probing

With Hot Disk® instruments, the Thermal Conductivity and Thermal Diffusivity of 2D anisotropic materials or components can easily and reliably be tested by using our Hot Disk® sensors. From a single measurement (assuming prior knowledge of the relevant Cp), the sensors provide the values in and through the plane of e.g. stacked sheets and layer composites – a unique feature among thermal conductivity meters!

Learn more from this Application Note >

In addition, the 3D Thermal Conductivity and Thermal Diffusivity tensors of 3D anisotropic materials can reliably be tested employing our dedicated Hot Strip® sensors. This 3D mapping requires some sample cutting of an area matching that of the sensor, and two individual measurements (again assuming known Cp) with the sensor oriented along two orthogonal axes of the sample. With this technique it is possible to characterize the values in, across, and through the fiber/grain-direction of e.g. fiber composites and rolled steel.

Learn more from this Application Note >

Furthermore exclusive to Hot Disk® instruments, localized structural changes, cracks, and voids can be identified inside materials or components. This via our Thermal Conductivity depth profiling capability, using Hot Disk® and Hot Strip® sensors. The unique depth-profiling capability enables defect scanning in QC scenarios that ranges from submillimeter range up to several centimeters into a sample. This is a feature only made possible by our instruments’ state-of-the-art precision regarding Thermal Conductivity.

Learn more from our scientific publication >

Global Services

and Support

With clients from a vast range of industries and research laboratories across the world, friendly and efficient customer service and support has long been crucial to Hot Disk. With our leadership and staff stemming from advanced academic backgrounds, we appreciate the importance of prompt service and clean, hassle-free operation when it comes to the use of our systems.

With near three decades of experience, Hot Disk today has an established network of distributors and business partners across the globe. Hot Disk sales and support representatives are available locally in over twenty locations worldwide, offering competent aid and advice toward all aspects of our famed systems.

Learn more about our sales network >

Our hub is appropriately located in Gothenburg, the commercial and industrial capital of Sweden. Here a dedicated team of software and hardware developers, as well as application specialists, are committed to help our clients with any issue that may arise.

Learn more about our head office >

To ensure smooth operative sailing, Hot Disk offers its clients perennially free instrument-software updates, a complimentary mobile phone utility app, as well as generous instrument guarantees and upgrade options. To a limited extent, we also offer refurbished instruments and contract testing.

Learn more about our services >

Looking for

QC-testing?

We have customers all around the world, linked to virtually all industries – robotics, automotive, aerospace, manufacturing, electronics, photonics, semiconductor, energy storage, construction, biotechnology, life sciences, food, textiles, and more. Many of them have successfully integrated our thermal QC-testing equipment into their production lines for composites or components – for example in the automotive industry for the automatic quality control of batteries, brake pads, and rubber tires.

Check out the hot topics in our publications database >

The easy, fast, and non-destructive testing furnished by Hot Disk® instruments make them ideal for rapid QC testing in time-sensitive production lines, where other (optical, acoustic etc.) QC testing either fails outright or is not sensitive enough. The Hot Disk® sensor is simply placed against the test object, and within seconds the Thermal Conductivity is probed to verify material quality or to find out-of-spec components before screen-out.

The thermal probing into the test object is anywhere between submillimeter scale to several centimeters deep, depending on application – all toward analyzing delicate variations in Thermal Conductivity. This latter property can either be determined as the average Thermal Conductivity of the probing volume, or as the local Thermal Conductivity within the probing volume. The unparalleled precision of our instruments allows for the rapid detection of <0.25% changes in Thermal Conductivity from test object to test object.

Check out these scientific papers on our instrument’s sensitivity > and our depth profiling capability.

We also offer tailored thermal QC testing equipment, including a QC line of cost-effective thermal conductivity meters and sensor switch units for multiple-point testing. To facilitate QC-testing in high-throughput robotic production lines, our equipment can be remotely controlled via TCP/IP protocol.

Learn more about our QC Instruments > and our sensor switch units.

We Hate Noise.

You Should Too.

Here’s Why.

The TPS technique has been made public via several review articles, as well as via our filing of the international standard ISO 22007-2. While we do not discourage others to develop their own equipment based on our TPS technique, it has proven difficult to approach the low noise levels we offer. Hot Disk has not disclosed the many, careful measures we have taken to minimize noise and thereby maximize precision. This is continuous work that is very important to us, and which we have been pursuing for over thirty years. It includes specialized manufacture and assembly of our sensors, optimization of our electronics, and advanced processing of our measurement data.

Witness our benchmark TPS 2500 S instrument which harbors an astonishing precision of 0.05% in Thermal Conductivity from repeated measurements on Stainless Steel – using a sensor as small as 12.8 mm in diameter. This impressive feature is made possible from the instrument’s unique temperature sensitivity of 17 micro-Kelvin! Even higher precision and sensitivity is achieved when employing a larger-diameter sensor, as it scales with size. In fact, our Hot Disk® instruments are occasionally used as precision heaters and/or ultra-highly sensitive thermometers in other applications than for measuring Thermal Conductivity. By way of example, they were recently used to analyze and confirm new physics of near-field radiation, published in Nature – c.f. S. Lang et al. 2017!

Find Your Instrument

- Updated

TPS 3500

The Hot Disk® TPS 3500 is the state-of-the-art instrument for testing the Thermal Conductivity, Thermal Diffusivity, Thermal Effusivity and Specific Heat Capacity of tiny, highly thermal conducting samples. The capabilities of the TPS 3500 go well beyond that of any other available instrument to date – Thermal Conductivity ranging from 0.005 to 1800 W/m/K, tackling 10-micrometer-thick slab samples, and accommodating temperatures from cryogenic to 1000°C. It has also the unique ability to analyse the anisotropic thermal transport properties of both uniaxial and biaxial materials, by use of specialized Hot Strip® sensors in the latter case. The TPS 3500 meets ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

TPS 2500 S

The popular Hot Disk® TPS 2500 S is the core instrument of our portfolio. This multi-purpose, highly performing R&D thermal conductivity meter is designed for precision analysis of thermal transport properties of materials of all types: solids, liquids, powders, and pastes. It is frequently used in automated production line QC testing. The TPS 2500 S handles sub-millimeter-thick bulk samples, has a Thermal Conductivity range of 0.005 to 1800 W/m/K, and accommodates temperatures from cryogenic to 1000°C. It can also analyse the anisotropic thermal transport properties of uniaxial materials. The TPS 2500 S is a capital research instrument, meets ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

TPS 2200

The Hot Disk® TPS 2200 is a general-purpose, affordable R&D instrument for accurate measuring of Thermal Conductivity, Thermal Diffusivity, Thermal Effusivity and Specific Heat Capacity, when performance and price are both in consideration. The TPS 2200 tackles a satisfying range of sample geometries, including down to millimeter-thick bulk samples. It can measure Thermal Conductivity from 0.01 to 500 W/m/K, and handles a temperature range from -100°C to 750°C. It can also analyse the anisotropic thermal transport properties of uniaxial materials. The TPS 2200 naturally meets ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

TPS 1500

The affordable Hot Disk® TPS 1500 is the ideal thermal conductivity meter for testing building materials, insulation materials or any other type of large bulk samples. The TPS 1500 Thermal Conductivity range comprises 0.01 to 400 W/m/K, and the instrument handles temperatures from -100°C to 750°C. Sample sizes down to a thickness of a few millimeters can be accommodated. It can also analyse the anisotropic thermal transport properties of uniaxial materials. The TPS 1500 meets ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

- New

TPS 1000

The Hot Disk® TPS 1000 is a powerful instrument for QC testing, measuring Thermal Transport Properties at very high precision. The TPS 1000 is scalable, where in its most basic configuration it functions primarily as a price-attractive simple Thermal Conductivity meter for 1D (through-plane) testing. Yet the TPS 1000 can also be used as a dedicated Specific Heat Capacity meter. In an upgraded configuration, the instrument can also be used as an advanced Thermal Conductivity, Thermal Diffusivity, and Thermal Effusivity meter, with performance and capability close to our TPS 2200 laboratory instrument. In other words tackles millimeter-thick bulk samples, measures Thermal Conductivity from 0.01 to 500 W/m/K, handles a temperature range from -100°C to 750°C, and be used to analyse the anisotropic thermal transport properties of uniaxial materials. The TPS 1000 meets ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

TPS 500 S

The Hot Disk® TPS 500 S rapidly and accurately measures the Thermal Conductivity, Thermal Diffusivity, Thermal Effusivity and Specific Heat Capacity of a wide range of materials and is therefore an excellent step-in thermal conductivity meter, and uniquely suitable for QC testing. The TPS 500 S adds powerful new features to the 500-series, in accommodating e.g. more measurement modules and sensor models. The TPS 500 S can handle bulk sample sizes down to a thickness of a few millimeters, has a Thermal Conductivity range of 0.03 to 200 W/m/K, and its temperature span is from -100°C to 300°C. It is partly based on ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

TPS 500

The Hot Disk® TPS 500 swiftly and accurately measures the Thermal Conductivity, Thermal Diffusivity, Thermal Effusivity and Specific Heat Capacity of a wide range of materials. It is therefore a favorable step-in thermal conductivity meter, and highly suitable for QC testing. The TPS 500 can handle bulk sample sizes down to a thickness of a few millimeters. The TPS 500 Thermal Conductivity range is from 0.03 to 100 W/m/K, and its temperature range from -100°C to 200°C. It is partly based on ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >

Hot Disk® M1

The Hot Disk® M1 is a basic thermal conductivity meter which nevertheless offers high accuracy and measurement repeatability. With the M1, solids, powders and pastes in the Thermal Conductivity range of 0.03 to 40 W/m/K are readily tested. Sample sizes down to a thickness of one centimeter can be handled, and the temperature range is 10°C to 40°C. The M1 is partly based on ISO 22007-2 and ASTM E3088-25, and is CE marked.

Learn more >